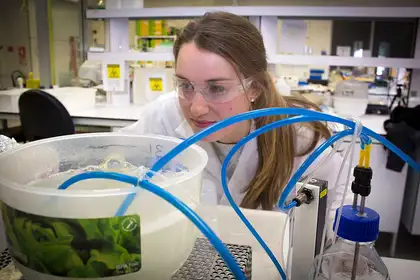

Alison Churchouse with her team's small-scale reactor.

Bachelor of Engineering (honours) student Alison Churchouse has a passion for waste, while some might find that odd, she knows it is a growing problem that is often overlooked.

But, before attending Massey University and developing that passion, the deputy-head girl at Whanganui Girls' College had her eyes set on a career in food technology.

“I was big into food at high school and I thought that’s what I want to do,” Alison says. “My parents never pushed me into any one area, they just told me to believe in myself and do what I want to do.”

So, she enrolled in a Bachelor of Food Technology, with the aim to move into a Bachelor of Engineering in her second year.

“First year was good because it's big and you get to study a broad variety of topics - the food techs and the engineers are in the same core papers, so you get to know a lot of people. Then you specialise into your chosen degrees and the class sizes get smaller, but you’ve still made those connections early on and seen a lot of different courses.”

One of her chemical bioprocess courses and her summer work experience at Axiam Plastics was to have a large effect on her study journey.

“When I was there I realised that this is what engineers do that's not food related. I just liked the idea of working in the high-tech factory and all the processes they had going on there, and I thought well maybe this is what I’m supposed to be doing.”

This led to a Bachelor of Engineering (honours) in Chemical and Bioprocess Engineering.

“Chemical Bioprocessing covers a lot – it’s where your food comes from, your fertilisers, your fuels, your plastic components, your metal components, your waste, all of that gets used every single day.

“I like seeing the whole system and I like the idea of being able to come out of my degree and go into an industry and help make more of an impact. Work on how people manage their waste or re-use or deal with their waste.

“Thankfully the degree is set up so you don’t make those choices till second-year, so I didn't lose any time changing what I wanted to do.”

But with all the options, why did waste management catch her eye?

“A lot of people are like ‘ew’ when you mention waste management, but I just think that there's just a lack of awareness about waste. People flush the toilet, take a shower, put something in the rubbish and think that's where it ends. And things like wastewater apply to so many more applications than just households. Factories and other businesses all have their own unique challenges. Take New Zealand, we can’t send our plastics to China any longer, so how will we overcome that?”

Brewing

Currently in her third year, Alison is enjoying the year-long study that focuses on the various stages of brewing beer.

“You get to learn about mass and energy balances, heat recovery systems, hazard analysis, noise and wastewater treatment. Site-reactor design, site layouts, personal protective equipment, how the operators were going to run it, everything to do with the system - inputs and outputs.

“We are just going through the waste side of it now. We currently have small-scale reactors up and running which we are monitoring and simulating the process of making the water safe. Finding the limits of the reactor and how far we can push it.”

Alison says the class sizes have been a highlight. “You get to approach the lecturers and get to know them quite well. You're not just another student amongst the masses. They know you and they're excited about their work and your projects.

Work Experience

As part of the degree, students must go out on work experience, and Alison visited Axiam Plastics sister-factory Axiam Metals in an administrative quality role.

“I worked under the quality control team, updating the process packs. This involved following a product from start to finish detailing each step involved in its production and quality assurance across all departments. This included understanding all the processes from molten metal injection casting, sand cast moulding as well as CNC [computer numerical control] machining and chemical conversion treatment for coating.

“Throughout this work experience, I learnt the importance of work place safety, quality regulations and following the processes determined by those in charge. I was specifically involved in developing and recording the process for six new components for an overseas customer.”

Fourth-year and beyond

With her fourth-year project coming up, Alison is talking with her lecturers to see what project might interest her, but what about a job?

Alison says she is not sure what she will be doing after her degree, but has a fair idea waste management will feature.

“I also think I would quite like to work towards managerial positions. I really enjoy working with people and the whole health and safety side of things as well.

“I want a nice job – but one that means I can have a life as well. I’m a dancer and I have just started volunteering for the Red Cross in Whanganui. It’s a deployment team - if there is a natural disaster, you can go help out with search and rescue, welfare and outreach.”

Alison has some advice for budding engineers.

"I think engineering is for people who like problem-solving - people who like being challenged. I like having stuff to work on, things that gets my mind ticking along. Engineering is great for people who want to make a difference. There's always going to be a need for engineers regardless of what major you do, whether it's food, mechatronics, electrical, civil or anything else.

About the Bachelor of Engineering (Honours) Chemical and Bioprocess Engineering

Chemical and bioprocess engineering is the industrial processing of raw materials to higher value products through combinations of physical, chemical or biochemical action. These processes can be very diverse and chemical and bioprocess engineers design, optimise and operate these processes.

Examples include fermentation of sugars to alcohol, production of pharmaceutical products, extraction of high value compounds, composting of organic waste, conversion of milk solids to dairy ingredients, conversion of wood into paper and the production of fuels from waste streams.