Featured

Plans to set up branch campus in Singapore welcomed by New Zealand Prime Minister

Last night in Singapore, Vice-Chancellor Professor Jan Thomas signed an Enhanced Collaboration Agreement with PSB Academy's Executive Chairman Viva Sinniah.

Veterinary Science soars in global rankings

The university’s reputation in Veterinary Science has been highlighted in the latest Quacquarelli Symonds (QS) Subject Rankings.

Weaving wisdom into a resilient future for Pacific students

Te Kunenga ki Pūrehuroa Massey University is pleased to present the ‘Weaving Wisdom into a Resilient Future 2024-2027 Pacific Plan’, a new student success plan that is guided by a Pacific lens.

Massey University awarded Five Stars Plus rating with QS Stars audit

For the third consecutive time, Te Kunenga ki Pūrehuroa Massey University has been awarded a Five Stars Plus rating from the international educational benchmarking agency Quacquarelli Symonds (QS).

Search all news

University news

Massey University signs MoU with Office of the Basic Education Commission in Thailand

Massey University and the Office of the Basic Education Commission (OBEC) within the Thai Ministry of Education have signed a Memorandum of Understanding which will open more opportunities for collaboration with the prestigious Princess Chulabhorn Science High Schools (PCSHS) network.

Plans to set up branch campus in Singapore welcomed by New Zealand Prime Minister

Last night in Singapore, Vice-Chancellor Professor Jan Thomas signed an Enhanced Collaboration Agreement with PSB Academy's Executive Chairman Viva Sinniah.

Veterinary Science soars in global rankings

The university’s reputation in Veterinary Science has been highlighted in the latest Quacquarelli Symonds (QS) Subject Rankings.

Weaving wisdom into a resilient future for Pacific students

Te Kunenga ki Pūrehuroa Massey University is pleased to present the ‘Weaving Wisdom into a Resilient Future 2024-2027 Pacific Plan’, a new student success plan that is guided by a Pacific lens.

Conversations That Count – Ngā Kōrero Whai Take

Conversations That Count – Ngā Kōrero Whai Take is a mixed media, podcast, editorial and event series brought to you by Massey University in partnership with The Spinoff. It provides a platform for the university and community experts to share their thoughts on how to overcome some of New Zealand’s biggest challenges.

Research news

Massey researchers secure funding to pioneer space-based earth observation studies

Two Massey researchers have been awarded funding to undertake globally important research that contributes to the understanding of our planet.

The impact of uniform design on female athletes’ confidence

New research from the School of Sport, Exercise and Nutrition has revealed the impact uniforms can have on female athletes’ anxiety and confidence levels.

To cultivate meat...or not to cultivate meat?

What’s at stake? Professor Joanne Hort tests the New Zealand market.

Dairy-free start-up creams it with $2.7 million ‘seed’ round

A start-up sprung out from research at Te Kunenga ki Pūrehuroa Massey University and the Riddet Institute has raised $2.7 million in ‘seed’ funding for its novel technology extracting plant-based milk from seeds.

Student success news

Championing excellence from triathlon to textbooks

Triathlete and postgraduate student Eva Goodisson is the first recipient of the International Sport Travel Fund for 2024, which saw her add the Oceania Sprint and Mixed Relay Triathlon Championships in Australia to her competition history.

Game, set, give: From class to court to charity

Entering his final year of professional tennis, alumnus Marcus Daniell intends to leave a lasting impact through his victories as well as through his sports-focused non-profit once he hangs up his racquet.

Unlocking career paths: A journey through the Bachelor of Sport and Exercise

The sport, health and wellbeing industry is one of New Zealand’s largest, providing a variety of employment opportunities in areas related to education, exercise, physical activity and sport promotion and administration.

Continuing the legacy for Ian Shirley Award recipient

Lena Bath has been awarded the Ian Shirley Award for 2023, acknowledging her achievement in the social policy courses while studying towards a Bachelor of Social Work (BSW) qualification.

Opinion and features

Opinion: Meeting the ever-changing needs of Aotearoa New Zealand

By Dr Tere McGonagle-Daly

Opinion: Let’s talk about equality – and the constitution

By Professor Richard Shaw

Opinion: The New Zealand Defence Force in 2024: The end of the peace dividend?

By Associate Professor William Hoverd.

Opinion: Prioritising connection over commercialisation this Christmas

By Associate Professor Kirsty Ross.

Awards and appointments

Academics receive Fulbright Scholar Awards to take their studies abroad

Two academics from Te Kunenga ki Pūrehuroa Massey University have been named recipients of 2024 Fulbright New Zealand Scholar Awards , which will see them take their studies international.

Te Kunenga ki Pūrehuroa Massey University welcomes new Chancellor and Pro Chancellor

The university has welcomed Alistair Davis ONZM and Angela Hauk-Willis into the roles of Chancellor and Pro Chancellor.

Brazilian Government honours Massey Professor

Professor Leonel Alvarado from the School of Humanities, Media and Creative Communication has been made an Officer of the Order of Rio Branco for his services to the Portuguese language and Brazilian culture in Aotearoa New Zealand.

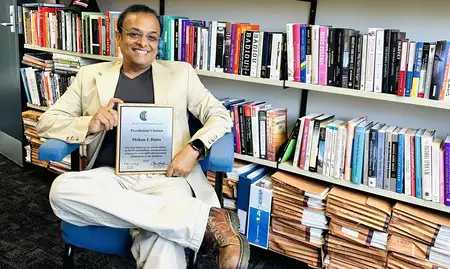

Professor Mohan Dutta’s academic-activism recognised with prestigious Presidential Citation

Professor Mohan Dutta has been recognised by the National Communication Association (NCA) with the Presidential Citation.

Massey News archive

View our collection of Massey News articles from 2003 to 2016.

@Massey Newsletter

All news

Massey University signs MoU with Office of the Basic Education Commission in Thailand

Massey University and the Office of the Basic Education Commission (OBEC) within the Thai Ministry of Education have signed a Memorandum of Understanding which will open more opportunities for collaboration with the prestigious Princess Chulabhorn Science High Schools (PCSHS) network.

Helping ākonga succeed through Kaihāpai mentoring programme

A mentoring programme that connects Māori students with Māori mentors to provide tailored support for their academic journey has helped more Māori students to pass and complete their courses.

Plans to set up branch campus in Singapore welcomed by New Zealand Prime Minister

Last night in Singapore, Vice-Chancellor Professor Jan Thomas signed an Enhanced Collaboration Agreement with PSB Academy's Executive Chairman Viva Sinniah.

Veterinary Science soars in global rankings

The university’s reputation in Veterinary Science has been highlighted in the latest Quacquarelli Symonds (QS) Subject Rankings.

For media enquiries

Communications and Public Affairs

- Phone

Jenna Nichols (Communications Manager – Corporate) +64 21 302 906

- Phone

Jemma Brackebush (Communications Manager) +64 21 660 260

- Subject experts

- Location

Postal address

Communications and Public Affairs

Massey University

Private Bag 11 222

Palmerston North

4442

New Zealand