Working with us

FoodPilot has access to a wide range of expertise and equipment across Massey's broad range of options. With the largest collection of pilot-scale food processing equipment in the southern hemisphere, we work with you to provide solutions to your organisation's food-related needs.

Customised solutions

From your idea to workshopping, information-gathering, lab scale testing and pilot scale testing, we know each project is unique. To help you meet the project needs, we can customise each step we help you with.

Consultancy

FoodPilot is ideally suited for the early stages of a project, including initial pilot-scale trials. In these stages, the focus is on developing and refining the formulation and process, and understanding the characteristics (shelf-life, sensory, functionality) of the product.

Once this phase has been completed, the project can be scaled up at one of our other New Zealand Food Innovation Network hubs for the first commercial runs, or larger-scale market validation.

Cost-effective services

We understand that funding research and development projects can be challenging, and we strive to make working with us as cost-effective as possible.

Talk to us about your project needs and costs. We can also take you through funding grant options you may be eligible for.

To help us get a better understanding of how we can help you, fill out this form.

Our services

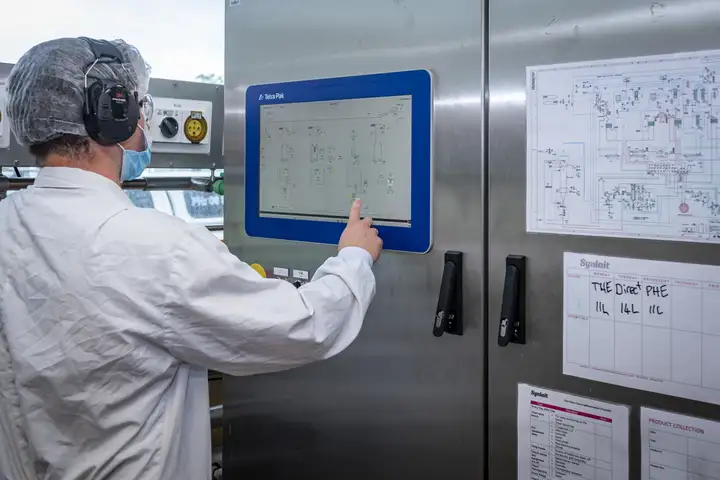

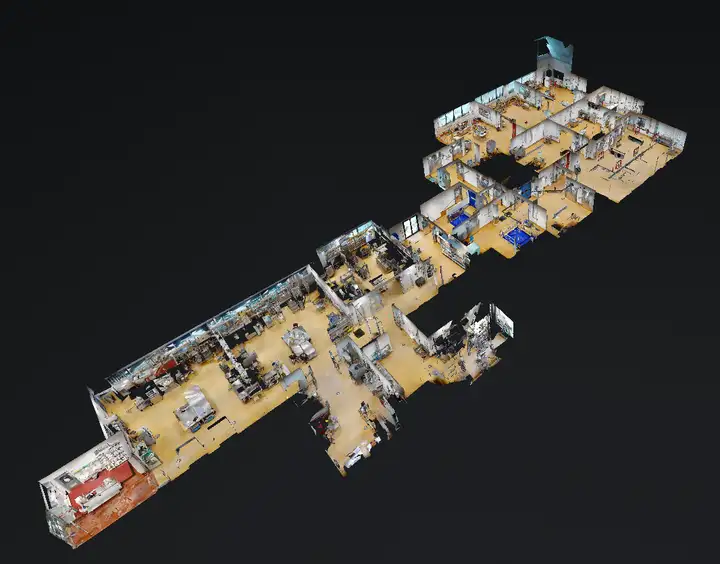

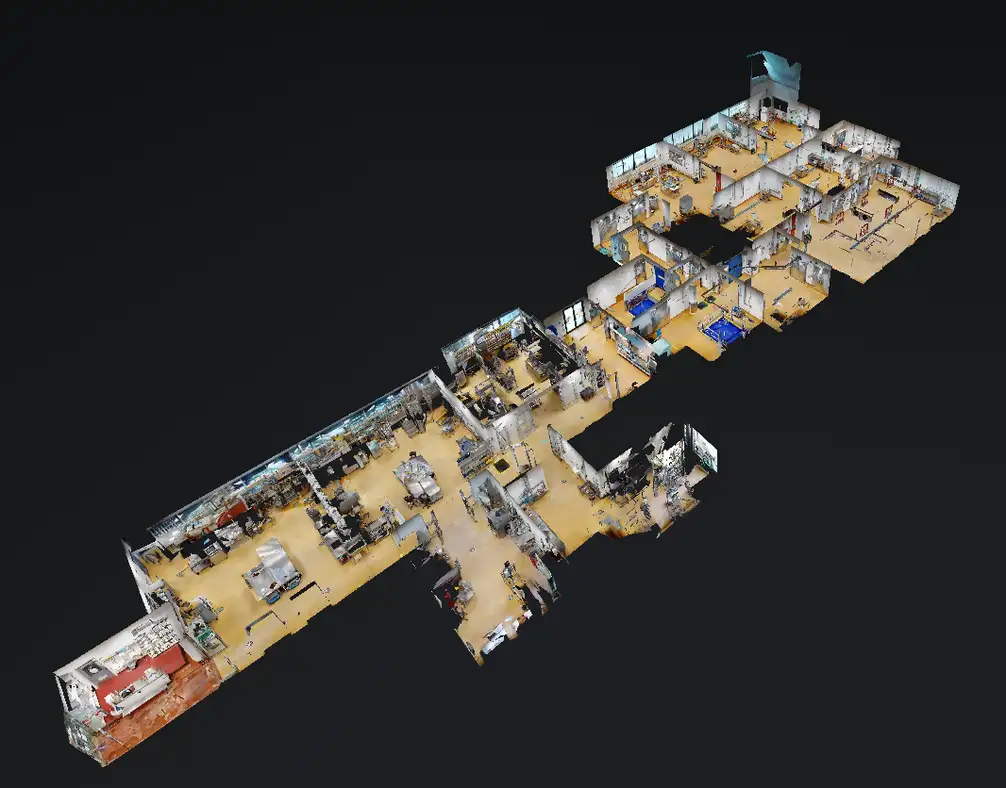

The FoodPilot is a thousand square metres of food-safe space, containing the largest collection of pilot-scale food and beverage equipment in the southern hemisphere.

Take a virtual tour of the FoodPilot

We can handle any material, whether it is for further research and development work, for export, or consumer research.

Services we offer include:

- workshops and ideation

- product and process development and innovation

- food safety

- shelf life determination

- consumer and sensory evaluation.

Book our facilities or ask a question.

Expertise and facilities

One of the many benefits of working with FoodPilot is the access we have to a wide range of expertise and facilities within Massey.

This means you can have a single project that draws in skills from across a variety of disciplines, and that we can connect you to experts in most areas.

We can coordinate Massey's extensive services, facilities and research expertise to meet your organisation's needs. As well as the food processing space within FoodPilot, many of our projects take advantage of specialist facilities within our wider network.

Explore our facilities

We have access to a wide range of expertise and facilities within Massey.

Beverage lab

Design, research and development of beverage products which offer:

- nutritional benefits

- wellness ingredients

- satiety

- performance enhancement.

Nutrition Laboratory

The laboratory specialises in analysing food, plant and animal products. The facilities enable nutritional testing of food products, including for:

- food safety

- labelling

- product formulation

- shelf life.

Human nutrition and dietetics facilities

Facilities for nutritional assessment and running clinical studies. These span multiple disciplines in the field, including human studies, animal studies, molecular and cellular biology, microbiology and biochemistry, and rheology.

Food characterisation laboratory

Equipment in this laboratory includes:

- Paar Physica MCR 301 and 302 control-stress rheometers

- texture analyser

- Instron universal testing machine

- spectrophotometers

- rapid-visco analyser

- Minolta colourimeter.

BodPod and other specialist equipment

The BodPod is an advanced piece of equipment used to accurately and easily measure your body composition. It uses an air-displacement method to measure all the fat in your body, which sets it apart from less direct techniques of body composition measurement.

Location: Manawatū (Palmerston North) campus

Food microbiology laboratory

The laboratory is capable of all the standard microbiological tests required by the food industry and has specialist equipment for:

- rapid microbial analysis (flow cytometry and impedance)

- biofilm work

- fermentation and molecular analyses (PCR).

The food microbiology laboratories are supported by academic and technical staff.

Companion animal nutrition

This facility specialises in nutritional research with emphasis on palatability testing of complete diets (or individual ingredients) and general nutritional adequacy testing.

Research can be carried out into all aspects of companion animal nutrition.

Engineering workshop

The FoodPilot engineering workshop is well equipped to enable us to modify existing equipment or design and build new items in order to meet specialist requirements.

FEAST Consumer and sensory laboratory and services

Sensory and consumer research, training and consultancy.

Facilities include:

- ISO standard sensory booths

- areas for running central location tests

- focus groups

- virtual reality testing.

Our partners

We work closely with a number of other facilities outside Massey.

NZ Food Innovation Network

We are part of the New Zealand Food Innovation Network (NZFIN), a national network that provides the facilities and the expertise needed to develop new products and processes, from idea to commercial success. To find out more how you can work with all our hubs, visit the NZFIN website.

Learn about the New Zealand Food Innovation Network

Food HQ

FoodPilot is also part of FoodHQ, a partnership between organisations with interests in food. Members include R&D and analytical service providers like Massey University, AgResearch, Plant & Food Research, the Riddet Institute, AsureQuality, ESR and the Cawthorn Institute. This partnership lets us pull together the best expertise from across these different organisations for large and complex projects.

Who we are

At the FoodPilot, we have skilled team of technologists, operators and technicians ready to support your projects. We also have access to all of Massey’s expertise across all disciplines; together we form the best project teams to solve your R&D challenges.

Nikki Middleditch

Before joining the FoodPilot as a senior food technologist, Nikki Middleditch spent over 15 years commercialising food products in the UK and Europe. Her manufacturing and brand-based experience spans a number of product categories. Nikki’s success at leading development projects is evident in products on European supermarket shelves, British casual dining menus, and within global QSR menus.

She credits her achievements to building strong relationships between her teams and clients “understanding what the clients’ needs are and taking them through the project with you, makes success much more meaningful not just for the client but for the teams behind the delivery of that new product”.

The FoodPilot has delivered similar successes with a wide range of NZ and international clients, ranging from start-up entrepreneurs through to multi-national companies.

Case studies

Read about some of the FoodPilot projects that we’ve undertaken for clients and how they’ve found the experience.

Natural Quinoa Puffs – making product dreams come true

The FoodPilot’s expert technologists helped Kate and Hamish Dunlop develop product recipes and processing methods to create their Natural Quinoa Puffs snack range. A variety of ingredients such as pumpkin and broad bean flours were formulated in with the quinoa to address quinoa’s underlying earthy, bitter notes but also to achieve a better texture and structure to the extruded snacks.

In addition, the FoodPilot’s extruder was the perfect machine to conduct all the experimentation as it is a scaled-down version of most commercial extruders therefore transitioning the process to the Dunlops’ manufacturer was seamless. The result of all this work at the FoodPilot? Crunchy, tasty, wholesome Quinoa Puffs, available at your local supermarket!

Converting desires and ideas into reality for Native

“We take our hats off to you, Native Apple & Feijoa” is the declaration of the top choice in a blind tasting of new to market, spirit-based RTDs by The Spinoff magazine.

Young brand Native have a lot to be proud of: taking an idea through to launch in less than a year, with the support of the FoodPilot. The successful development of Native’s hard sparkling lies in the great relationship and trust they had with the FoodPilot.

“A lot can be said about the support we have had to get to where we are now, however a key point to raise that comes from all 4 of the Native co-founders is that we always had confidence in the FoodPilot. It was new territory for us to cross, yet the FoodPilot and Massey were professional, easy to approach and collaborative with channeling our desires and ideas into a reality” – Luke McBride from Native

Exceeding Kaitahi as One's expectations

Multi-award winning Kaitahi as One have big ambitions. What started as an opportunity to create healthy kai and jobs for the iwi have led them to successful product launch of frozen smoothy drops with some help from the FoodPilot at Massey University.

“There is no word other than amazing for what they have been able to do for us. We are all new to food manufacturing, so we have so many questions. In fact, we didn’t even know what all the words were in this business! We had an idea, so the learning curve to make it real and get a product onto shelves was immense. The team at FoodPilot explained everything and went well beyond what we had anticipated. They took us patiently through all the technicalities and have come up with incredible solutions to every challenge.” – Arohaina Owen, Kaitahi

Converting Pamū deer milk into high value powder

The first New Zealand deer milk to be exported for use in the Asian cosmetic industry as well as local fine-dining restaurants, was developed and processed at the FoodPilot. Pāmu’s relationship with the FoodPilot spans many years of research and development to get to this world first launch.

“Massey FoodPilot supported and enabled Pāmu to process Pāmu Deer Milk into high value powder. Deer Milk has a completely different composition to bovine milk, as such, processing comes with its challenges, the product behaved differently at each step of the handling process. A notable hurdle was the absence of equivalent “Deer Milk” regulatory standards, therefore producing compliant product was an ambiguous task, due to a world first innovation.” – Claire Hannan, Pāmu

Contact us

FoodPilot

- Hours

9am to 5pm, Monday to Friday

- Phone

- Location

FoodPilot

Riddet Complex

University Avenue

College of Sciences

Massey University

Palmerston North 4474

Book our facilities or ask a question.

Related content

School of Food Technology and Natural Sciences

New ideas in food science and food technology, alongside the fundamental sciences of chemistry and biology.

College of Sciences

The College of Sciences seeks innovative solutions to challenges facing our world.

Feast lab

The Food Experience and Sensory Testing (Feast) laboratory is a hub for sensory and consumer research, training and consultancy.

Nutrition Laboratory

Massey's Nutrition Laboratory specialises in analysing food, plant and animal products through research and testing.